In chemical processing, especially in chemical plants and laboratories, handling sour fluids is a critical operation that requires careful consideration of the materials and components used in piping systems. Ball valves are one of the most critical components in these systems. However, not all ball valves are created equal, especially when handling corrosive substances. This article delves into the types of ball valves suitable for handling sour fluids, the challenges posed by valve leakage, and the importance of selecting the right materials to ensure safety and efficiency.

Understand the function of ball valve

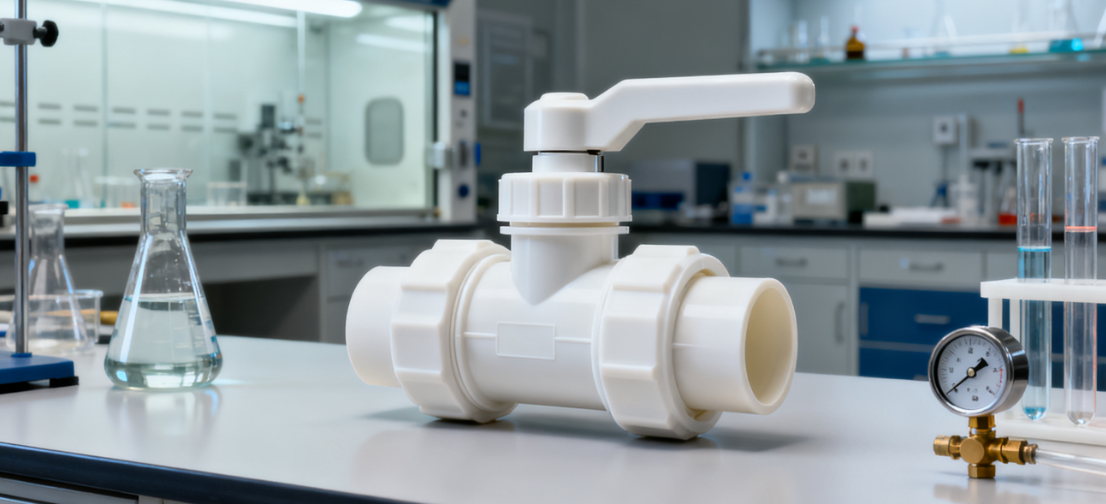

Ball valves are widely used across industries for their reliability and ease of operation. They consist of a spherical disc (ball) that controls the flow of liquid through the valve. Rotating the ball controls the flow of liquid, making it an effective on/off control solution. Chemical plants and laboratories often transport acidic liquids, so the choice of ball valve material is crucial to prevent leakage and ensure the valve’s longevity.

Challenges of Valve Leakage

One of the most significant issues facing chemical plants is leaking valves, especially when handling corrosive acids. Leaking valves can lead to hazardous situations, including environmental contamination, personnel safety risks, and costly downtime. The cost of repairing a leaking valve is often far greater than the initial price of the valve itself. This is because extensive cleanup, replacement of damaged equipment, and lost production time may be required.

Corrosion: The Main Problem

While metal valves have traditionally been used in many applications, they are particularly susceptible to corrosion when exposed to acidic fluids. The corrosive nature of acids can quickly degrade metal components, leading to premature failure and leakage. Therefore, selecting the right valve material is crucial in chemical processing environments.

Choose the right material

When conveying acidic liquids, the material used in ball valves must be corrosion-resistant. PVC (polyvinyl chloride) and PTFE (polytetrafluoroethylene) are two of the most effective corrosion-resistant materials. Both materials offer excellent corrosion resistance, making them well-suited for use in chemical plants and laboratories.

PVC ball valve

PVC ball valves are lightweight, durable, and resistant to a wide range of chemicals, including many acids. They are ideal for applications where weight and ease of installation are important. PVC valves are also less expensive than metal valves, making them a cost-effective solution for handling acidic liquids. However, it’s important to ensure that the specific type of acid being handled is compatible with PVC, as some strong acids can still cause degradation over time.

The Importance of Valve Design

In addition to material selection, the design of a ball valve plays a crucial role in its performance and ease of use. One important feature to consider is the handle design. An easy-to-turn handle allows for quick and efficient operation, which is especially important in emergency situations where rapid closure is required. Valves with ergonomic handles can reduce operator fatigue and improve overall workplace safety.

Maintenance and inspection

Regular maintenance and inspection of ball valves is essential to ensure their continued performance, especially in environments handling sour fluids. Operators should be trained to recognize signs of wear and corrosion, such as discoloration or pitting on valve surfaces. Implementing a routine inspection procedure can help identify potential problems before they lead to leaks or valve failure.

Repair and Replacement

When a valve begins to show signs of wear or leakage, operators must decide whether to repair or replace it. In many cases, the cost of repair can far exceed the valve’s initial price, especially if the damage is extensive. Therefore, investing in high-quality, corrosion-resistant valves from the outset is often more cost-effective, reducing the likelihood of leaks and the need for repairs.

Ultimately, choosing a ball valve for handling acidic fluids in chemical plants and laboratories is a critical decision that impacts safety, efficiency, and cost. PVC and PTFE ball valves offer excellent corrosion resistance, making them ideal for handling corrosive substances. Furthermore, the valve’s design, including ease of operation, plays a crucial role in ensuring safe and efficient use.

By understanding the challenges posed by valve leakage and the importance of material selection, operators can make informed decisions that improve the reliability of their chemical processing systems. Investing in high-quality ball valves and performing regular maintenance can significantly reduce the risk of leaks and associated costs, ultimately making chemical plants and laboratories safer and more efficient.

Post time: Oct-24-2025