I’ve found that pvc ball valves are a game-changer for managing water flow in small irrigation systems. Their compact design fits perfectly into tight spaces, while their sturdy construction handles daily use with ease. Adjusting water flow becomes effortless, whether you’re working with drip systems or mini-sprinklers. These valves make irrigation simple and efficient.

Key Takeaways

- PVC ball valves are small and useful, perfect for small irrigation systems. They fit well in tight spaces and help control water flow easily.

- These valves last long and do not rust, which makes them durable. They can handle strong chemicals, so they work well for many irrigation tasks.

- Checking and cleaning PVC ball valves often stops problems and keeps them working well. Taking care of them saves money on fixes and keeps your irrigation system working properly.

Benefits of Using PVC Ball Valves in Irrigation

Compact and Versatile Design

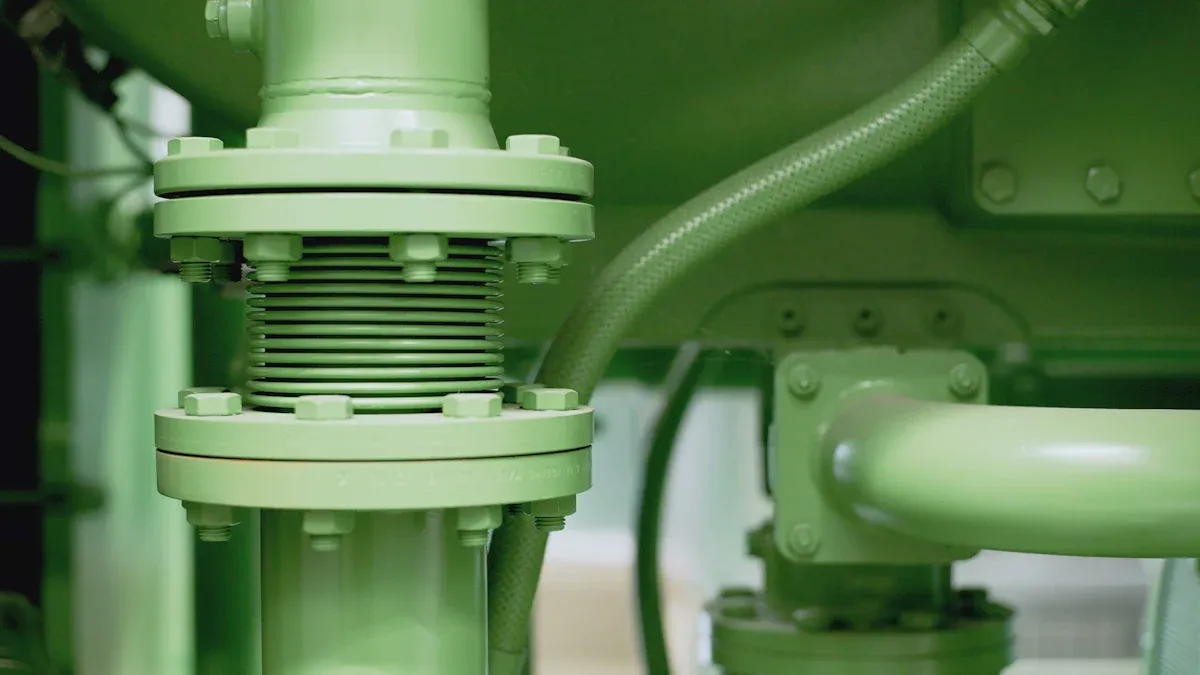

I’ve always appreciated how PVC ball valves fit seamlessly into various irrigation setups. Their compact size makes them perfect for tight spaces, especially in small-scale systems like drip irrigation. These valves come in a range of dimensions, ensuring they meet different needs.

| Dimension | Measurement Range |

|---|---|

| Nominal Size | 1/2 inch to 2 inch (72 mm to 133 mm) |

| Overall Length | 2 to 4 inches (133 to 255 mm) |

| Overall Width | 1/2 to 4 inches (20 to 110 mm) |

| Height | Varies with handle type and size |

This versatility allows me to use them in multiple applications without worrying about compatibility. Whether I need to control water flow in a mini-sprinkler system or a more complex setup, these valves deliver consistent performance.

Durability and Chemical Resistance

PVC ball valves stand out for their durability. The high-quality PVC material resists corrosion and compression, making it ideal for long-term use. I’ve noticed they don’t rust or scale, even when exposed to harsh conditions.

- PVC Schedule 40 offers excellent corrosion resistance.

- It’s suitable for solvent cementing or threading.

Additionally, these valves handle chemicals like sodium hypochlorite with ease. This chemical resistance ensures they remain functional in environments where other materials might fail.

| Chemical | Resistance Level |

|---|---|

| Sodium Hypochlorite | Resistant |

| Various Chemicals | High Resistance |

Cost-Effective Solution for Home Irrigation

When I compare PVC ball valves to brass or stainless-steel options, the cost savings are clear. They’re the most affordable choice for home irrigation systems. Their resistance to wear and corrosion extends their lifespan, reducing the need for frequent replacements. This makes them a smart investment for anyone looking to manage water flow efficiently without breaking the bank.

- PVC ball valves are more affordable than brass or stainless-steel alternatives.

- Their durability minimizes replacement costs over time.

By choosing PVC ball valves, I’ve been able to create a reliable and budget-friendly irrigation system that meets my needs.

Installing a 1/4 Inch PVC Ball Valve

Tools and Materials Required

Before starting the installation, I gather all the necessary tools and materials. This ensures a smooth process without interruptions. Here’s what I typically use:

- A 1/4 inch PVC ball valve

- PVC pipes and fittings

- Pipe cutter or hacksaw

- PVC primer and cement

- Adjustable wrench

- Teflon tape for sealing threads

Having these items ready saves time and prevents unnecessary delays.

Step-by-Step Installation Process

Installing a PVC ball valve is straightforward when I follow these steps:

- Prepare the Pipes: I cut the PVC pipes to the required length using a pipe cutter. I make sure the edges are smooth and free of debris.

- Apply Primer and Cement: I apply PVC primer to the pipe ends and the valve sockets. Then, I coat them with PVC cement for a secure bond.

- Attach the Valve: I insert the valve into the pipe ends, ensuring proper alignment. I hold it in place for a few seconds to let the cement set.

- Seal Threaded Connections: For threaded connections, I wrap Teflon tape around the threads before tightening them with an adjustable wrench.

- Inspect the Installation: Once everything is in place, I check for leaks by running water through the system.

This process ensures a secure and leak-free installation.

Avoiding Common Installation Errors

I’ve learned that avoiding mistakes during installation is crucial for optimal performance. Here are some tips I follow:

- Install the valve with the correct orientation based on the actuator type.

- Use sealing gaskets if the pipeline design requires them.

- Tighten flange bolts symmetrically and evenly to prevent leaks.

- Perform a post-installation inspection to ensure smooth operation and proper sealing.

By following these steps, I avoid common issues like misalignment, leaks, or improper sealing. This keeps my irrigation system running efficiently.

Maintaining Your PVC Ball Valve for Optimal Performance

Regular Cleaning and Inspection

I’ve found that regular cleaning and inspection are essential for keeping PVC ball valves in top condition. Dirt and debris can accumulate over time, affecting performance. I make it a habit to clean the valve surfaces and remove any buildup. Routine inspections help me spot potential issues early, like cracks or worn seals, before they escalate.

Here’s why I prioritize maintenance:

| Benefit | Description |

|---|---|

| Longevity | Regular maintenance extends the lifespan of valves, reducing the need for replacements. |

| Security and safety | Proper maintenance helps prevent accidents and ensures compliance with safety regulations. |

| Reduced need for shutdowns | Maintenance can often be performed without shutting down operations, minimizing production losses. |

| Cost savings | Regular inspections and maintenance reduce unexpected repair costs and keep operational expenses lower. |

| Regular cleanings | Clean valves prevent debris buildup, which can impair performance and lead to failures. |

| Routine inspections | Frequent checks help identify issues early, preventing costly repairs and ensuring reliable operation. |

By following this approach, I ensure my irrigation system operates smoothly and efficiently.

Troubleshooting and Repairs

When a PVC ball valve malfunctions, I troubleshoot the issue step by step. Seals are often the first component to fail, so I check them for wear or damage. For one-piece and two-piece valves, replacing the entire valve may be necessary. However, three-piece valves allow me to replace seals without removing the valve completely, saving time and effort.

Here’s my troubleshooting checklist:

- Inspect the seat, disc, stem, and packing for damage.

- Check the actuator if the valve isn’t functioning properly.

- Examine seals for corrosion or wear.

If I find faulty components, I replace them immediately. I also verify wiring connections, control circuits, and power sources to ensure everything works correctly. This systematic approach helps me resolve most issues effectively.

Knowing When to Replace the Valve

Despite regular maintenance, there comes a time when replacing the valve is the best option. I look for signs like persistent leaks, cracks in the body, or difficulty in turning the handle. If repairs don’t restore functionality, I opt for a new valve. Replacing a worn-out valve ensures the irrigation system remains reliable and efficient.

By staying proactive with maintenance and knowing when to replace components, I keep my irrigation system running at its best.

A 1/4 inch PVC ball valve has transformed how I manage water flow in my irrigation system. Its durability, affordability, and ease of use make it a reliable choice.

Proper installation and regular maintenance ensure long-lasting performance. I recommend this valve to anyone seeking an efficient and hassle-free irrigation solution.

FAQ

How do I know if a PVC ball valve is compatible with my irrigation system?

I check the valve size and pressure rating. Matching these with my system ensures compatibility. Most 1/4 inch PVC ball valves fit small-scale setups.

Can I use PVC ball valves for hot water applications?

No, I avoid using PVC ball valves for hot water. They perform best with cold water systems due to their temperature limitations.

What should I do if my PVC ball valve leaks after installation?

I inspect the connections for loose fittings or improper sealing. Wrapping Teflon tape around threads or reapplying PVC cement usually resolves the issue.

Post time: Mar-26-2025