Factory Outlets Homeholds mould Factory for Vancouver

Short Description:

Product Detail

Product Tags

To be the stage of realizing dreams of our employees! To build a happier, more united and more professional team! To reach a mutual benefit of our customers, suppliers, the society and ourselves for Factory Outlets Homeholds mould Factory for Vancouver, Competitive price with high quality and satisfying service make us earned more customers.we wish to work with you and seek common development.

Product Detail

Quick Details

| Place of Origin: Zhejiang, China (Mainland) | Product Material: P20H, 718H, 2316, Nak80, S136 | Mold life: 30K, 50K, 100K | HRC: 32-48 |

| Brand Name: none | Product: homeholds mould | Runner: hot or cold | Payments item: half and half |

| Model Number: EHMH13 | Name: vertical plastic injection molding machine | Software: Pro-E, UG, regular worker, CAD | T1 time: 30days after drawing confirmed |

| Shaping Mode: Plastic Injection Mould | Other name: household mold type, chair, container, fox | Mold base: LKM, ODM | Guaranty: 1 year |

Packaging Delivery

| Packaging Details | Wooden carton |

| Delivery Details | 35-45 DAYS |

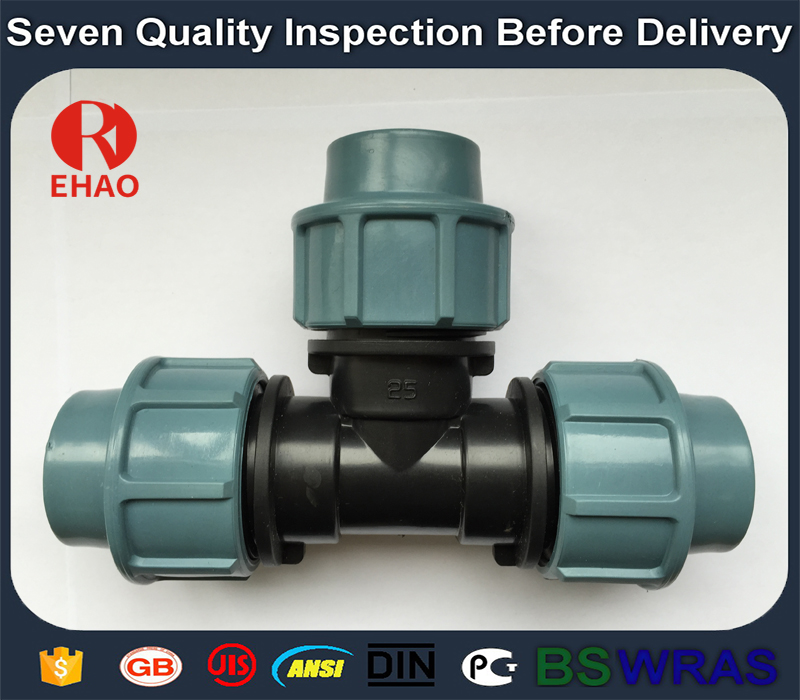

vertical plastic injection molding machine

Product Description

Specifications of vertical plastic injection molding machine:

| mould material | 45#, P20, H13, 718, 2738, NAK80, S136 etc. |

| mould base | LKM, HASCO etc. |

| Cavity | Single/multi |

| Mould life | P20: 300,000-500,000 shots 2316 718H: 500,000 shots S136 H13: 700,000 shots |

| Design software | UG, PROE, CAD etc. |

| Plastic material | PP, PE, ABS, PC etc. |

| Delivery time | 35-45 days |

| Specification | According to client’s requirements |

1. Samples/drawing&requirement from you

2. Mould design: we will communicate and exchange the opinion with you after you place order.

3. Material Purchase: Steel cutting and mould base tooling.

4. Assembling.

5. Inspection of mould: following and controlling the tooling processing.

6. Mould testing: We will inform you the date. Then will send the sample’s inspection report and injection parameters with the sample to you!

7. Your instruction&confirmation for shipment.

8. Ready-made mould before packing.

Package of injection molding:

1. Wooden carton,

2. shipping by sea, by load,

3. We also can produce any plastic parts for you. We have 25 different ton injection machines.

Pictures of vertical plastic injection molding machine:

Company Information

1. Office corner

2. Equipment

3. Working place

4. Package and delivering

5. Certification

6. Our customers

FAQ

Why choose us?

| Prompt response in 24 hours |

| Good Quality |

| Reasonable price |

| Stronger engineer team Support R&D |

| Good After-sale service |

How about your payments item?

Payment Item: 50% deposit after confirming the drawings and 50% balance after confirming the samples (before delivery).

Delivering time?

Generally, T1 time is 30 days after drawings confirmed both side, then the samples approved, 5 days later it can be delivering.

Ability of producing?

We have all tooling machine for making molds. We can provide 30-50 sets of molds every month.

Welcome to visit us!

Chuangyuan Mould Factory is a professional plastic pipe fitting moulds manufacture in China.

Ian ([email protected])

Http:// www.cnfittingmould.com

Http:// www.cnpipingmould.com

Addr: No.8 Xinglong Rd.,West Indystrial zone,Huangyan,Taizhou,Zhejiang,China

Website:https://www.cnworldsvalves.com/

Mail:[email protected]

About us:

TIANJIN WORLDS VALVE CO., LTD.is located at TIAN JIN BIN HAI where is only 3 kilometers away from Tianjin Xingang Port,TIANJIN WORLDS VALVE CO.,LTD. is a specialized manufacture enterprise that focuses producing, installing, sale and service. The main products include Center Line Butterfly Valve, Flanged Butterfly Valve, Metal Butterfly Valve, Check Valve, Gate Valve, Waterpower Control Valve, Microresistance Slow Close Check Valve, Multi-function Pump Control Valve and their series products. Moreover, we can produce control valve and pressure reducing valve that are different materials, pressures, specifications, actuation ways. Our products include more than 50 serials and 1200 species, and the annual production output is more than 8.000 metric tons. WORLDS valves have been selling well all over China and exporting to Europe, America and other countries and areas, which are used widely in water supply and drainage, electric power, petrol chemical industry, metallurgy and other trades. Our products are quite creative, good quality, cheap price and excellent credit, so customers trust our products.