plastic pvc bibcock : 1)high quality and 0.5 million times lealess 2)light weight and beautiful appearance

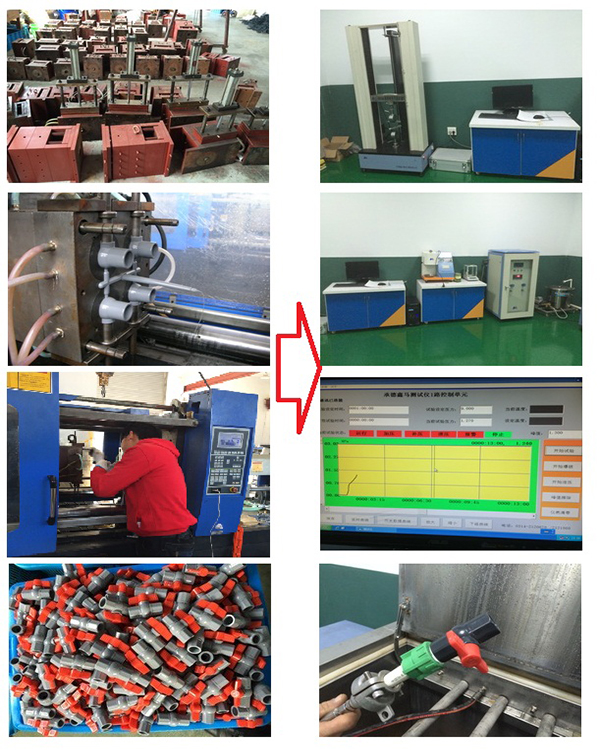

1.DESCRPTION

1)material pvc

2)size 1/2″,3/4″ 3)water pressure 0.6

4)temperature resistence from-10deg to 45deg

5)warranty have long service life

6)no fade,no canker,no aging

-EPDM seal and O-ring. - Easy to turn tee handle. - Testing pressure 225PSI at 73F, working pressure 150PSI at 73°F. - Rated temperature range at 40°F to 125°F continuous, up to 140°F

2.APPLICATIONS

1)Cold water supply facilities for public budings

2)Food,Chemical and Electronic industry pipeline networks,such as pipelines for transporting all kinds of corrosive liquids

3)Drinking water production system pipeline networks,such as pure water and mineral water pipes

4)Air conditioning facality pipelines and swimming pools

5) Compressed gas pipeline networks for industry use