Factory wholesale 360t metal injection molding machines Factory in Armenia

Short Description:

Product Detail

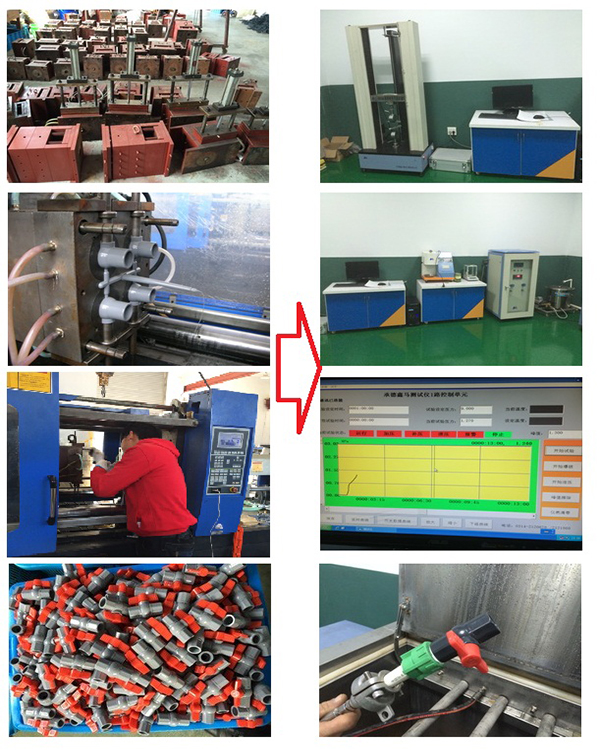

Valve factory

Injection mold factory

Extrusion factory

Product Tags

we can offer high quality products, competitive price and best customer service. Our destination is "You come here with difficulty and we give you a smile to take away" for Factory wholesale 360t metal injection molding machines Factory in Armenia, Looking to the future, a long way to go, constantly striving to become the all staff with full enthusiasm, one hundred times the confidence and put our company built a beautiful environment, advanced products, quality first-class modern enterprise and work hard!

| NO. |

|

BRAND | Made from | |||

| ITEM | ||||||

| 1 | HI FUNCTION CONTROLLER WLSEC08-A900 | EST(MACHINE UNDER 410T ) | China | |||

| 2 | HI FUNCTION CONTROLLER WLSPEC10-A900 | EST(MACHINE ABOVE 460T ) | China | |||

| 3 | SERVO DRIVE | INNOVANCE | China | |||

| 4 | GEAR PUMP | SUMITOMO | JAPAN | |||

| 5 | SERVO MOTOR | PHASE | ITALY | |||

| 6 | Electro-hydraulic proportional pressure valve | NORTHMAN | TAIWAN (For machine above 360T) | |||

| 7 | Transducer | NOVO or Gefran | Germany or Italy | |||

| 8 | Air breaker | Schneider or Siemens | Germany | |||

| 9 | Contactor | Schneider or Siemens | Germany | |||

| 10 | Switch | Schneider or Siemens | Germany | |||

| 11 | Limit switch | Omran | Japan | |||

| 12 | Directional valve and Pilot valve | Vickers or Rexroth | US or Germany | |||

| 13 | Logical access module hydraulic valve Chase Drive | Function combination | Match | |||

| 14 | Clamping hydraulic differential module | Function combination | 1 | |||

| 15 | Hydraulic motor for preplasticizing | Intermot/Dandun | Italy | |||

| 16 | Rapid ejection module | Function cimbination | 1 | |||

| 17 | Core×2 sets | No valves | ||||

| 18 | Core plug×4 sets | with 2 valves | For machine above 600T | |||

| 19 | RPM detect | Function combination | 1 | |||

| 20 | Hydraulic safety | Function combination | For machine above 270 | |||

| 21 | Electricial safety | Function combination | 1 | |||

| 22 | Mechanical safety | Function combination | 1 | |||

| 23 | Hose pipe | Continental or Goodyear | Germany or US | |||

| 24 | Seal rings | Hallite | UK | |||

Packaging Delivery

| Packaging Details: | Wooden carton |

|---|---|

| Delivery Detail: | 35-45 DAYS |

360t metal injection molding machines

| Secifications | 360/2180 | |||||

| Item | U/360W | |||||

| SCREW TYPE | A | B | C | D | ||

| INJECTION UNIT | SCREW DIAMETER | mm | 60 | 67 | 70 | 75 |

| LENGTH RATE DIAMETER | L/D | 24.6 | 22 | 21.1 | 19.7 | |

| SHOT SIZE(THEORETICAL) | cm3 | 947 | 1181 | 1289 | 1480 | |

| INJECTION WEIGHT | g | 862 | 1075 | 1173 | 1347 | |

| INJECTION RATE | g/s | 278 | 346 | 378 | 434 | |

| INJECTION PRESSURE | MPa | 231 | 186 | 170 | 148 | |

| SCREW SPEED | r/m | 200 | ||||

| CLAMPING UNIT | CLAMP TONNAGE | KN | 3600 | |||

| OPEN STROKE | mm | 675(705) | ||||

| SPACE BETWEEN TIE-BARS | mm | 680×680 | ||||

| MAX MOULD HEIGHT | mm | 720 | ||||

| MIN MOULD HEIGHT | mm | 250 | ||||

| EJECTOR STROKE | mm | 180 | ||||

| EJECTOR TONNAGE | KN | 70 | ||||

| OTHERS | MAX PUMP PRESSURE | MPa | 16 | |||

| PUMP MOTOR POWER | KW | 37 | ||||

| HEATER POWER | KW | 24.7 | ||||

| NUMBERS OF HEATING AREA | Segment | 4+1 | ||||

| MACHINE DIMENSIONS(L×W×H) | m | 7.38×1.95×2.55 | ||||

| OILTANK CUBAGE | L | 510 | ||||

| MACHINE WEIGHT | t | 13.5 | ||||

Specifications of 360t metal injection molding machines:

1.Samples/Drawing &Requirement from you

2.Mould design:we will Communicate&Exchange the opinion with you after you place order.

3.Material Purchase:Steel cutting and Mould base tooling.

4.Assembling.

5.Inspection of mould : following and controlling the tooling processing.

6.Mould testing:We will inform you the date.Than will send the sample’s inspection report&injection parameters with the sample to you!

7.Your instruction &confirmation for shipment.

8.Ready made mould before packing.

Pictures of auto lamp mould of manufacturer:

Package of auto lamp mould of manufacturer:

1. Wooden carton ,

2. shipping by sea ,by load ,

3. We also can produce any plastic parts for you . We have 25 different ton injection machine .

| Why choose us? |

| 1, Prompt response with 24hours. |

| 2,Good Quality. If as technical skill Lifelong free repair. |

| 3,Reasonable price. |

| 4, Stronger engineer team Support R&D. |

| 5, Good After-sale service |

1. How about your payments item ?

Payment Item:50% deposit after confirming the drawings and 50% balance after comfirming te samplse(before delivery).

2. Delivering time ?

Generally , T1 time is 30 days after drawings confirmed both side, then the samples approved , 5 days later it can be delivering .

3. Ability of producing ?

We have all tooling machine for making molds, we can provide 30-50 sets of molds every month .

150T pet injection molding machine

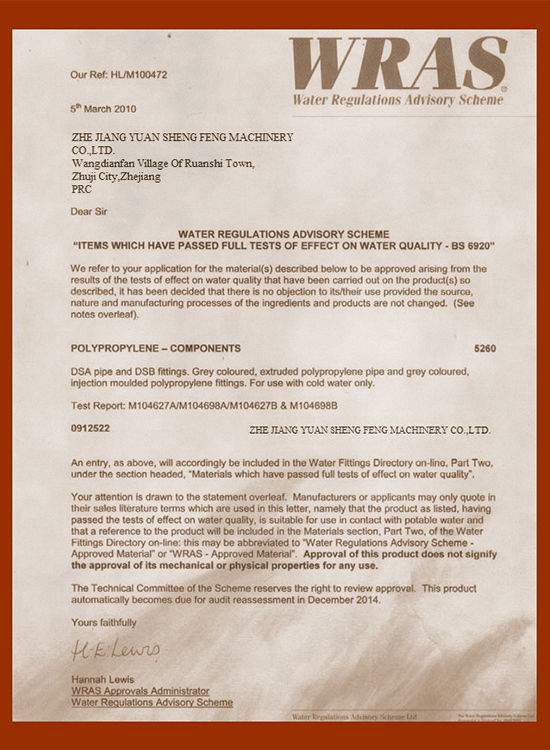

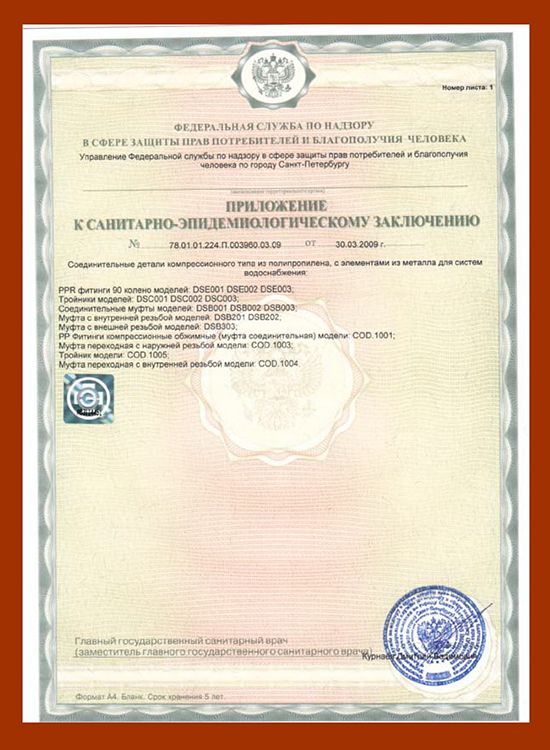

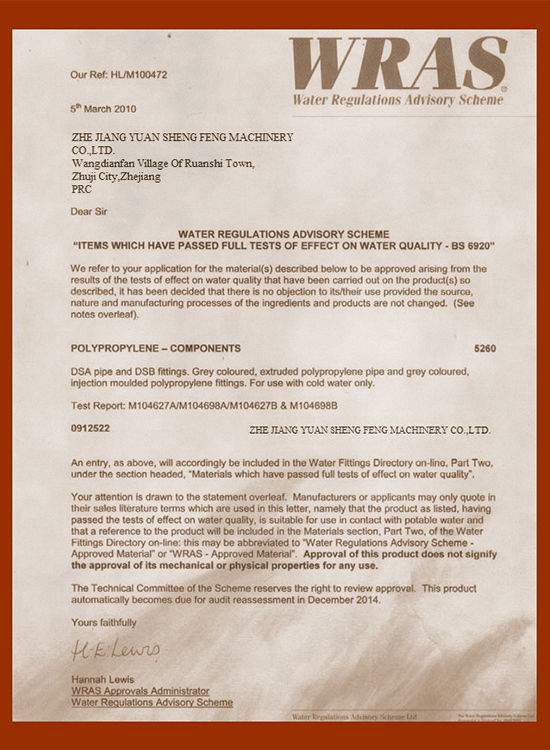

4 . Certification

4 . Certification

web:https://www.gmkvalve.com/

Email : sales@gmkvalve.com / info@gmkvalve.com

GMK VALVE was located in longwan town,wenzhou city of Zhejiang,where is the China Pump & Valve hometown.

The main products of our company include ball valves, gate valves, globe valves, check valves, butterfly valves, plug valves,strainer valves, power station valves,and gas valves ect. Size from 1/2″ to 88″ (DN15 to DN2200);Pressure from 150Lb to 2500Lb (PN1.0Mpa to PN42.0Mpa); materials cover WCB, WCC, WC6, WC9, CF8, CF3, CF8m, CF3M, LCB, LCC, A105, 304, 316, 304L, 316L, F11, F22, LF2, F51,B148, ALLOY 20, UB6, Titanium, Hastelloy, Inconel,duplex stainless steel, Monel, Monel etc.

The products are widely applied in petroleum, chemical industry, natural gas, electric power, metallurgy, pharmacy, pulp & paper, urban construction and long transportation pipeline projects. Our products are sold well worldwide include America, Europe, Southeast Asia, Middle East and Africa ect. Certificated with ISO9001, API6D, CE/ PED.

We has established the technical research, development center and quality inspection center with a relatively sound management system.

In addition, it has introduced advanced manufacturing technology from aboard, and has advanced machining centers, CNC machine tools, metal cutting and processing equipment, physical and chemical testing equipment, nondestructive tester, spectrum analyzer, valve comprehensive performance tester and other equipment to ensure the products reach the purpose of zero leakage.

We insist on the concept of ” Quality first,Prestige important”, a well-trained and dedicated team including engineers,technicians and other employees, This allows us to offer customers quality product,competitive price and prompt delivery time.

We always work hard to improve our existing products and pursue new ideas and ways to stay ahead of the every changing market.With our professonal and experience hope can enlarge your market and obtain a new brilliance in the future .

The current status of my corolla CE, after I posted the video back in 2013 about installing my radio and some leds. I’ve done many things since then:

NOT shown on video: •Megan Racing lower middle bar. •Ultra Racing rear strut bar

•TRD Front strut bar

•OEM rear bumper cover

•LEDs everywhere replacing the yellow bulbs, including shift selector and those in rear view mirror.

•Dash cover

• Window visors

•Full THULE roof rack

•Corolla LE Chrome accents (e-brake & A/C vent tips)

•Corolla LE dual compartment arm rest (from a 2003 LE)

•Chrome door handles (will buy OEM ones soon)

•Corolla LE/S tweeters & tweeter covers (from a 2004 LE)

•2005-2008 Corolla LE cluster (from a 2005)

•Corolla LE woodgrain console and switches (from a 2007)

•Corolla LE/S rear view mirror (from a 2005 LE)

•Intermitent wiper switch (from a 2004 LE)

•eBay foglight kit (holding up good until now)

•Hikaru 6000k HIDs on fogs and low beams.

•Still rocking the blue halogen bulbs on the high beams, the same ones from the 2013 video.

•Sickspeed black socks on PS and brake reservoirs and intake mani (for looks)

•Engine cover is from a 2002 celica, with Synth Oil only (car has been synthetic since 100k miles, it has 130k)

•Big 3 Upgrade

•Fumoto valve for easier oil changes

•Alternator, starter, engine mounts, cv and ball joints, and exhaust maintenance has been done.

•AEM drop in filter

•Pyle alarm with starter disable and trunk opener.

•Steering wheel toyota logo replaced since it was scratched.

•TRD seat belt covers (Given to me for free by a friend, another toyota enthusiast)

Plans:

•03-04 1ZZ-FE supercharger (will take some hunting to do)

•DC sports headers w/ Magnaflow high flow converter.

•2ZZ water pump

•MWR water pump and alternator pulleys.

•Lightweight crankshaft pulley (1ZZ engine is internally balanced, no need for heavy stock pulley.)

•Tokico Blue shocks or KYB shocks.

•Poly bushings in control arm and rear axle beam.

•I already have Tein H tech springs I haven’t installed yet.

•I have 2005 Celica GT-S wheels I will be installing soon.

May 17-23, 2017: repainted my rear bumper with spray can, and last using rust oleum clear coat, pretty amazed for a spraycan job, bumper was dull and scratched.

° All of the things I mentioned on the car, done by myself completely.